So, after a bit on tinkering I got the 3D scanner at my work figured out. NextEngine HD is sort of an odd device in that precision is not really super necessary in terms of replicating distance and positions, but super precison is needed to link all scans into one mesh.

The basic concept with the scanner is to get overlap. You want data points form every millimeter of your object. The scanner itself asks from how many angles you want to scan for each capture on the turntable Four angles means it with look at the object and then scan, turn your object 90 degrees and look and scan again...so on four times. Eight angles means your object is turned 45 degrees each time. And so on up and down the scales I think that upper range of angles in 20 (maybe). A quick scan might take 7 minutes, a good scan 15 minutes, and a superior scan 25 minutes just from eight angles. The NextEngine scanner is nice in that you could scan a whole car or a two inch statue using that same technique...that car might require 400 scans off the turntable where as the tiny statue might only need three on a turntable.

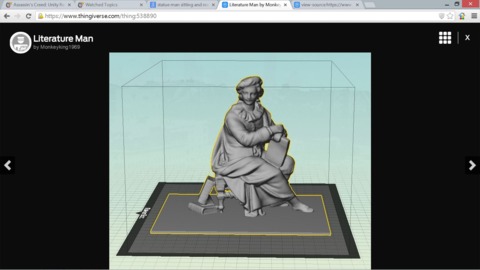

Here was my first successful scan turned into a printable STI file

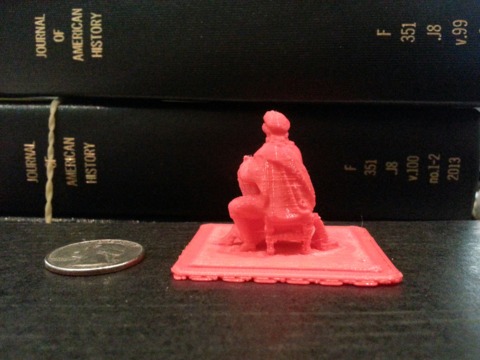

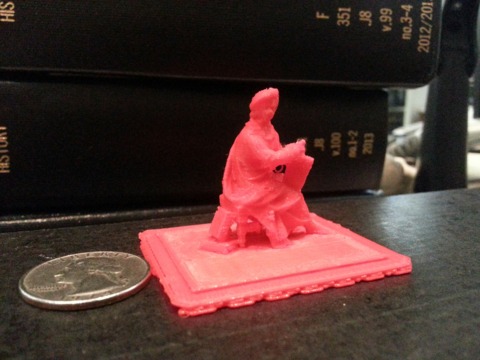

To capture that man on a stool with his flowing robe I had to scan a 7 inch statue fives times, each time from eight angles 1) Level on a platform once around. 2) The front of the state tilted up 30-30 degrees to capture more data especially under his right arm a full 360. 3) Tilted from the back to capture more data from his arm and in his lap a full 360 4) Tilted from the right side to capture even more date from any odd angles 5) The whole statue on its side to capture the top, bottom, front and back better from a 360 view.

All of those scans took about 22 minutes each, then add some time to clean any extraneous data from the scan that was captured in error. Finally, I spent 30 minutes linking up at least three points (and up to six points) of reference from each scan to stitch everything together. The computer was, in effect, taking data from each of the five scans of each data sets each to combine all 40 views of the object into one 3D mesh.

Simple objects might not need five scans, but at least two are needed for any useful scan of even a simple object. And, even for my object I could have scanned it more times from even more extreme angles to capture more parts of the statue that were still hidden.

Yet, even after all the above when you finally have a 3D mesh, there are still holes in your object. Parts that the scanner simply could not see, seams the scanner could not closed, etc. Thus the final part of finishing your mesh is to file holes manually and/or automatically. Even after sculpting a few of the larger holes 'artistically' the mesh might have very small holes you might miss without a millimeter by millimeter inspection, so you have to have the computer close those anyway. I chose to make my model watertight (close every pin hole) simply to allow for it to 3D print smoothly.

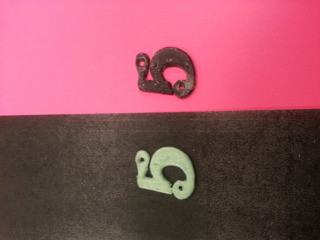

My resulting mesh was 6" high, but I printed it at 25% to test it. Below was a fast print to show my work.

This link below will bring you to my "Thingiverse" page for the above object:

Log in to comment