I'm SICK of all your crap.

By emkeighcameron 82 Comments

I make no apologies for my potentially offensive blog title.

Simply because it's entirely true. Though not in the sense you probably assumed. This blog post is a public service announcement! And also part of a quest, but hey, I'm not spamming like everyone else! I have a purpose!I am here to educate you all about a subject near and dear to my own heart:

Where does the poo go?

That's right. Poo. Crap. Shit. Big brown bombs. Turds. Ass candy. Cornhole gold. Or as we in engineering call it: "biosolids".

I bet you never ever thought about this before, huh? You just take a seat on your toilet, let 'er rip on out, and then flush the little magic lever that whisks away your 8-hour breakfast to a magical, unknown place. Those holes in the street? Who KNOWS what they're for, right? Who CARES?

Well, I'm here to break it down for you, kiddos. Here's a nice, brief overview of what happens to your crap. And hopefully, by the end of this, you'll be a little less prone to knee-jerk reactions against the hard-workin' guys and gals at your local sanitary district. All right, let's get started.

STEP 1: You crap, you flush, and it begins.

I was considering putting an image in for the crapping step, but (wisely) decided against it. Most home toilets hook into the sewer mains via lateral pipes as shown in my totally awesome Paint image below. [Yes, yes, okay, some people have septic tanks, but let's ignore them for the sake of brevity.]

And away it goes! If you care, lateral pipes are usually about 4 inches in diameter, while sewer mains can range up to several feet across (I've stood upright inside 8-foot mains before, it's pretty crazy.)

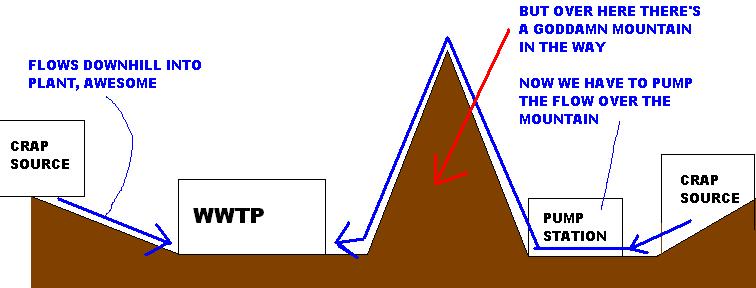

STEP 2: Snakes and Ladders

Protip for anybody who is thinking about designing a sanitary collection system: water (and shit) flows downhill. That's why, most of the time, you'll find wastewater treatment plants (WWTPs) located at the lowest possible elevation. In valleys, in canyons, etc. That way, the majority of the flow simply comes straight to the plant! Sometimes, though, there's stupid hills or mountains in the way, and that's when you need pumping stations. You might see some of these pumping stations throughout your neighborhood. They're usually pretty clearly labeled with big "PUMP STATION" signs and "STAY THE HELL OUT" signs.

You gotta give credit to the guys that maintain the pipelines that run throughout our cities. These underground pipes are very difficult to install, very difficult to repair (impossible, really), and pretty dangerous to work with. Most older pipelines in the U.S. are made from concrete, and many of our older systems are suffering from terrible corrosion issues nowadays. Newer pipes tend to be PVC (or some other plastic) which are far more corrosion resistant. Usually, when a concrete segment fails, the district goes in and just replaces it with a PVC segment, rather than trying to repair the concrete.

This is what the inside of a typical pumping station looks like. Those long, gray, cylindrical things are the pumps themselves, and they pump away 24/7 pushing your shit up and over the elevations in your district, so that it can ultimately get to the WWTP.

Step 3: The Plant

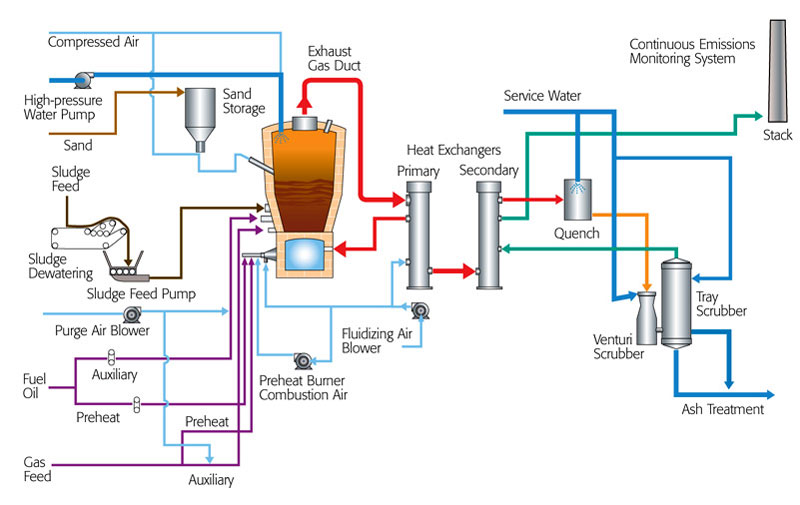

Understanding a wastewater treatment plant is.......well, it's fucking complicated, and I'm sure as hell not going to explain every aspect of it. Look at the picture below if you're curious. (And yes, I COULD explain every single one of those damn things, I just don't wanna). Plants range vastly in size. A "moderate" plant will handle about 45 million gallons per day of incoming sewage, and that can quadruple (or more) in big wet weather events.

Let's pause for a second and consider that. Say the "average" flow is 45 million gallons per day (MGD). But the peak flow, during a huge storm, might be 250 MGD. You have to design your plant to operate at that WHOLE range. From, say, a 30 MGD minimum to the 250 MGD maximum. That's a goddamn HUGE design range. That's nuts. That means that, on average, 80% of your plant will be unused. But you need that capacity there to handle the wet weather events! And if you don't have it, you get fined, sued, and fired when overflows start happening. (An overflow is simply a backup in the sewage line, usually resulting in manholes popping off and sewage spraying into people's homes and so forth. The EPA simply loves overflows because it gets to fine the sewage district shit-tons of money any time one happens).

All you really need to know is the following order for how a WWTP works:

1) You take the heavy things out of the flow (tree branches, skateboards, you name it)

2) You take smaller things out of the flow (sand, grit, pebbles, etc.)

3) You separate the flow into two components: sludge (biosolids) and liquor (stinky brown water)

4) The sludge goes one way, and the liquor goes another.

What we're going to talk about is the sludge. Sludge is a generic term for the concentrated flows of biosolids that you start seeing at the end of the plant process. You see that thing called the "sludge thickener" in the picture above? That's right about where we're going to start paying attention. That device is taking all the sludge lines that have been created so far (there's a couple which come from different parts of the plant) and it mixes them all together into one, uniform flow.

Yes, this is exactly as disgusting as it sounds. It's stinky, pathogenic, disgusting, slimy, and horrible. Sludge is the third-worst thing you can imagine at a WWTP. Don't worry, we'll get to the other two.

Step 4: Killing the Sludge

How do you get rid of all this horrible sludge? Well, there's two ways: burning it and digesting it. I'm deliberately omitting a step here, that step being DRYING the sludge, because I have a great/horrible story about that that I'm saving for the end.

INCINERATION

I absolutely love incineration. In most places (especially here in California) it gets a bad rap because people are idiots and don't know the first thing about engineering. The common belief is that it's not "green" because it has fire and smoke, so it MUST be dirty. The truth is it has almost exactly the same greenhouse gas emissions as the "green" way of destroying biosolids, digestion (which we'll cover in a second). The best kind of incinerator is called a Fluidized Bed Incinerator, and you can see it below. It's basically a huge can full of sand. You heat it up with natural gas, then throw some sludge in there. The sludge burns, and as long as you keep adding more sludge, the temperature stays high enough to maintain combustion (that means you can cut the natural gas feeds, it will keep running with just sludge). You also make a LOT OF HEAT which you can use to make steam, which can be used to spin turbines, which make electric power that you can use around the plant. So that's pretty cool.

DIGESTION

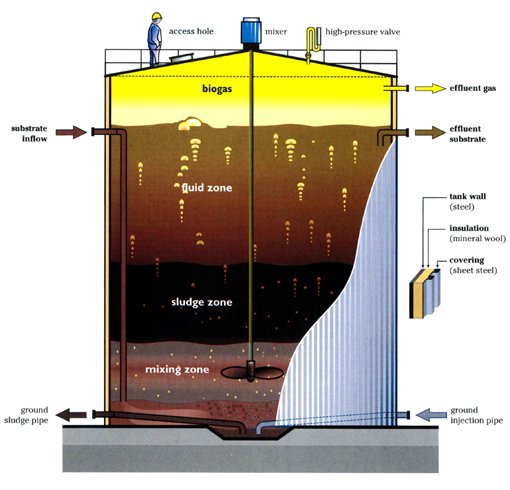

You gotta marvel at the majesty of Creation, because sure enough, there are some microorganisms ("bugs", as we say) out there that just can't wait to eat your shit. That's exactly what an anaerobic digester tank takes advantage of. It's a huge, "bug" rich, stomach tank. You pump in sludge, the "bugs" inside eat it up and fart out methane gas, and then you take the methane gas and burn it. You can get energy out of burning that methane, which is a big draw for plants to use digestion.

And that's pretty much how you destroy crap. There's more to it, of course. A LOT more. But I think this is a pretty good quick and dirty (ha) overview. Read on if you wish to hear a truly sad, disgusting story about the fall of a noble man.

The Legend of Gary

Remember how I said I omitted a step? Drying the sludge? Well, it turns out that you don't want to incinerate really wet sludge. Go figure. Most mixed sludge lines are about 5% actual sludge and 95% water. Protip: Don't try to burn water, it doesn't fucking work.

So you want to dry that out somewhat. A good incineration value is 22% sludge and 78% water. (That sounds like it's still a lot of water, but this is really as far as you can dewater most sludges in common practice.) This 22% sludge is called the "cake". Because it has pretty much the same consistency of a nice, soft cake. A cake made of shit. Hyper-compressed, concentrated, compacted, warm, gooey, shit.

So how do you dry the cake? You don't want to do it thermally. Again, like I said, it's stupid to heat water. So you use mechanical means. A nice big belt press, or in Gary's case, a centrifuge.

Gary, from that day forward, would be forever known as "Chili Dog" among his fellow plant workers. Upon opening that hatch, a veritable flood of rich, creamy cake covered Gary from head to toe. He cried out for help, and suffice it to say that his situation did not improve. After being hosed down outside the building, Gary went home early that day. About two weeks later, Gary's skin color returned to its normal hue.

That's all, folks. Thanks for reading, and maybe next time you take a fat dump, think about all the poor schmucks that it might traumatize.

Oh and hey, if any mods feel like checking me out, you know, that would rock.