Brewing Beer with Andy - PAX East 2016 and a Super Secret Beer! (Pictures and GIFs!!!)

By Brewmaster_Andy 35 Comments

Hi everyone! Brewmaster Andy here, back with another foray into the world of homebrewing beer! Over the past year, I have continued to make even more additions to my brewery. I moved off the porch and into the basement by converting my kettle to run on an electric element, and I've recently moved my whole setup to a friend's airplane hangar complete with utility washing station and floor drainage system.

This year, I have four beers brewing - between the Giant Bomb panel, brewing for Cards Against Humanity, and another beer for a secret panel - featured here - I've been pretty busy!

Setup and Heating

These days, my brewery consists of the following equipment:

- A 15.5 gallon "keggle" with a sight glass, 5500w electric element wired to a 240v plug and a control panel, and a return valve

- A 10 gallon mash tun made out of a round beverage cooler, with a return valve and using a 12-inch stainless steel false bottom for filtering

- A custom made RIMS (Recirculating Infusion Mash System) tube with a RTD temperature sensor, mounted with a 1500w electric heating element and wired to a control panel

- Control panel with temperature control for the 1500w element and control for a high-temperature liquid pump

For today's brew (a super secret beer for PAX), I was brewing a hoppy pale ale. Anyone interested in the recipe can PM me!

I started my day by heating up the full volume of water I would need for this 5.5 gallon batch - 12 gallons. I filled my kettle and turned on the heating elements. One of the benefits to using an entirely electric setup is the quick and easy heating process. It's no joke heating 12 gallons of liquid to 168 degrees, but because my element is mounted in my kettle directly and is using the full 5500w to heat only the liquid itself, it only takes about 20 minutes.

Mashing

One of the most important parts of the brew day is the mash process. This is the process by which the starch in grain is converted to sugar, and is what makes the beer fermentable. For today's recipe, I needed to heat my mash to 154 degrees. The initial volume of water I had been heating is actually overheated, in order to compensate for temperature loss when adding the grain to the water. Once it's ready, I pump it over to my mash tun, and then slowly add the grain and stir gently.

I then need to set up a recirculation to maintain my temperature. The liquid is pumped out of the mash tun, into the pump, out of the pump, into the RIMS tube and past the temperature probe, out the RIMS tube, and back into the mash tun. The probe relays the current temperature to the temperature controller in the control panel toolbox, so that it knows when to fire the element to maintain temperature.

This recirculation process serves two roles: maintaining temperature, and clearing the liquid. At this stage, the liquid is called "wort."

This recirculation process will continue for an hour, during which I use a sous vide circulator to maintain the temperature of the other half of the initial 12 gallons of water that I heated. Once it's done, I pump the liquid into the kettle for heating.

Sparging

However, this isn't enough liquid to boil and create beer with, so I need to "sparge," or rinse, the grains to my desired boil volume. I do this by adding additional heated water and then pumping the beer into my kettle. I monitor the boil volume using my sight glass. The next several GIFs show this transfer process.

Boiling

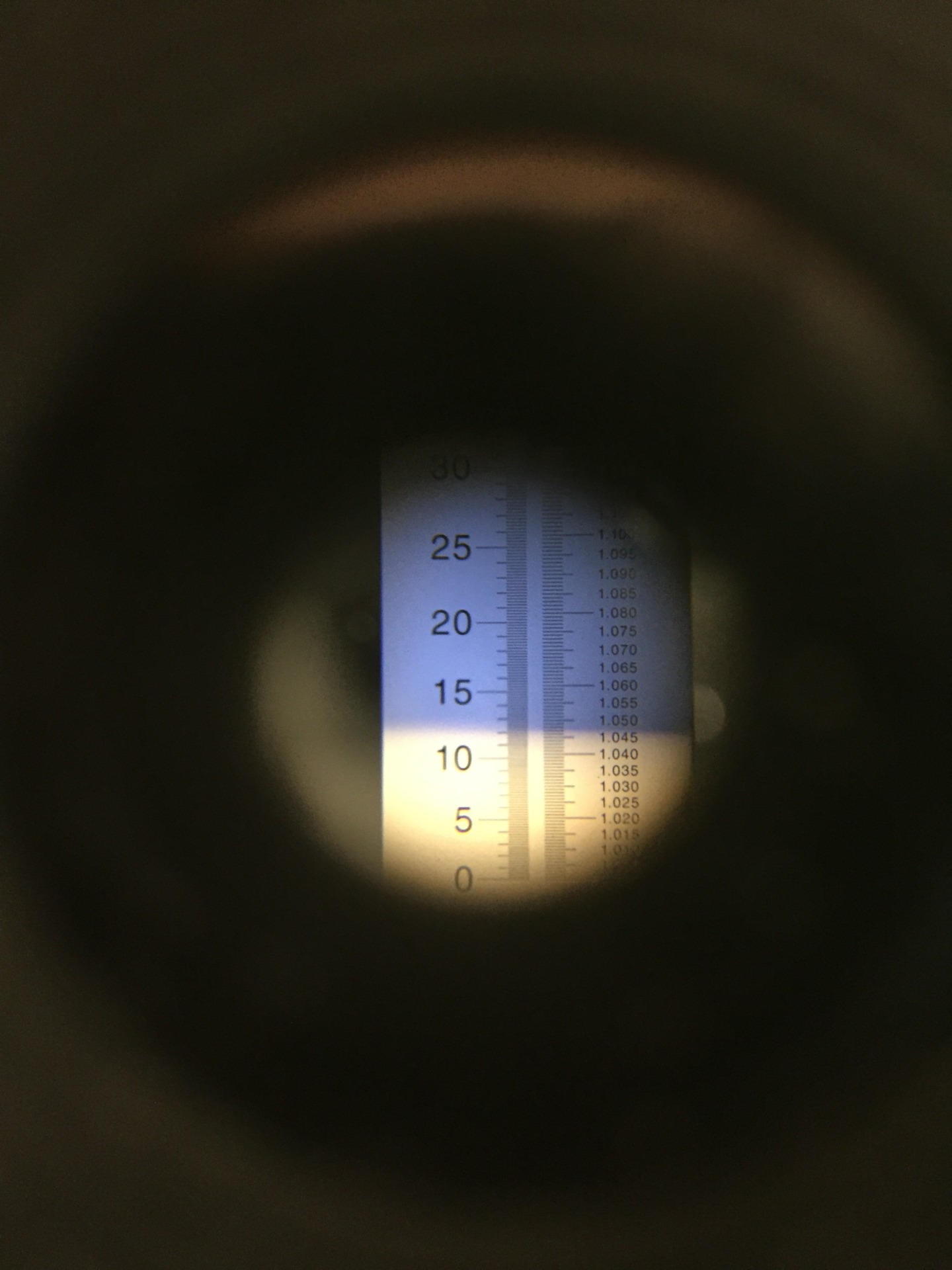

Once I reach my desired boil volume (for this batch, 9.5 gallons), I take a measurement of my specific gravity using a refractometer. This measures a liquid's sugar content and let's me know if my numbers are on par for the anticipated alcohol % I planned this beer for.

As the beer comes to a boil, a layer of foam coagulates along the top of the liquid surface. I use a special liquid called "Ferm Cap" to reduce the chance of excess build up of this foam and a potential boil over.

After that, it's just a matter of adding hops at specific times and boiling for an hour!

I'll add more to the comments as the beer gets closer to being drinkable and as always, I am happy to answer any questions!

See you at PAX East!